Key Rules for Interior Systems

For interior dust collection systems, NFPA 664 offers specific guidelines for controlling combustible dust hazards. These systems must effectively collect and contain dust to prevent it from escaping into the workspace.

- Air Filtration and Recirculation: Interior systems that recirculate air must include high-efficiency filters capable of removing 99.9% of combustible dust from the air to maintain safe indoor air quality.

- Dust Accumulation Limits: Dust accumulation should not exceed 1/32 inch over 5% of the floor area. This standard is critical for engineers to manage, as even small amounts of dust accumulation can present a significant fire hazard.

- Fire and Explosion Protection: Systems must have fire suppression and explosion protection features, such as spark detection and extinguishing systems in the ductwork. Explosion vents or suppression systems should also be installed to manage pressure buildup in the event of an explosion.

- Maintenance and Housekeeping: Regular maintenance, including filter replacement and duct cleaning, is essential to keeping dust collection systems compliant. Engineers should conduct frequent inspections to ensure systems meet NFPA standards and minimize dust buildup. Regular maintenance—including filter replacement and duct cleaning—is critical for compliance. Engineers must inspect systems frequently to ensure they meet NFPA standards and minimize dust buildup.

Key Rules for Exterior Systems

For woodworking facilities with exterior dust collection systems, NFPA 664 and NFPA 68 outline clear rules to prevent explosions and ensure safe dust management.

- Placement and Distances: Exterior dust collectors must be located at a safe distance from the building to prevent damage in the event of an explosion. NFPA 664 typically requires these systems to be placed at least 30 feet from the facility.

- Explosion Venting: Systems are required to have explosion venting that safely directs blast pressure away from structures and personnel. Engineers must ensure that the system is designed to handle the pressure from a potential explosion without causing additional hazards.

- Weatherproofing and Durability: Outdoor systems must be resistant to environmental factors such as rain, wind, and extreme temperatures. Ensure all ductwork and equipment are corrosion-resistant and sealed for long-term durability.

- Grounding and Bonding: Static electricity can easily accumulate in outdoor dust collection systems. To prevent ignition, NFPA requires that all equipment, ductwork, and machinery be properly grounded and bonded to dissipate static charges safely.

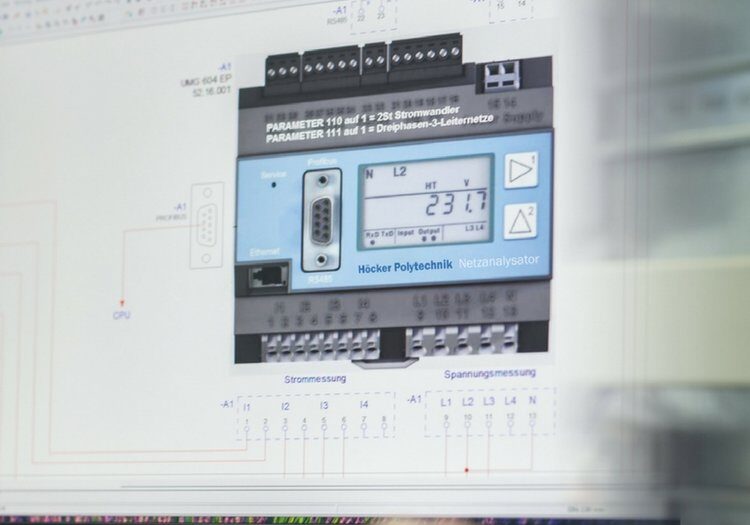

Pro Tip: Install pressure sensors and static monitors in both interior and exterior systems to track real-time performance. These tools help engineers ensure compliance with NFPA limits on dust accumulation and pressure buildup, optimizing both safety and efficiency.

Pro Tip: Install pressure sensors and static monitors in both interior and exterior systems to track real-time performance. These tools help engineers ensure compliance with NFPA limits on dust accumulation and pressure buildup, optimizing both safety and efficiency.

![JB1_20171218_00084_preview[1] JB1_20171218_00084_preview[1]](https://hockeramerica.com/wp-content/uploads/bb-plugin/cache/JB1_20171218_00084_preview1-1024x576-landscape-058e06ffcab491e0754d8eabda55517c-.jpeg)