In today’s industrial world, energy efficiency isn’t just an advantage — it’s a game-changer for cutting costs, boosting sustainability, and optimizing performance.

Höcker Energy Management Systems are built to revolutionize your operations, slashing energy consumption by up to 60%. These smart, programmable systems adjust fan speeds and air volume in real time, minimizing waste and extending equipment life. Whether you're handling a high-demand pneumatic conveying system or a paint spray exhaust, our technology adapts to your needs, ensuring fans operate at peak efficiency no matter the load. Flexible and scalable, Höcker systems fit seamlessly into both new installations and retrofits.

Key Benefits

Product Insights

Smart Tech. Simple Integration.

A Power Flex Move

Höcker’s Energy Management Systems operate on a smart platform that continuously monitors and adjusts fan speeds based on real-time production needs. When a machine goes offline, the system reduces fan speeds to match the lower demand, saving energy while still ensuring safe, effective waste extraction.

Precision Control at Every Step

At the heart of this efficiency are frequency inverters, developed specifically for air conveying fans. These inverters dynamically adjust airflow to the exact volume required, ensuring your fans only run when needed, eliminating unnecessary energy waste.

Retrofitting for Efficiency

One of Höcker’s standout features is its ability to retrofit into existing pneumatic and paint spray systems. Whether or not your exhaust system was supplied by Höcker, this technology can transform any setup into an energy-saving powerhouse.

Smart, Easy Integration

Programming the system is as simple as setting a microwave. Once installed, it operates automatically, cutting energy usage and delivering long-term savings. Plus, its soft start feature reduces strain on motors, extending equipment lifespan and minimizing noise.

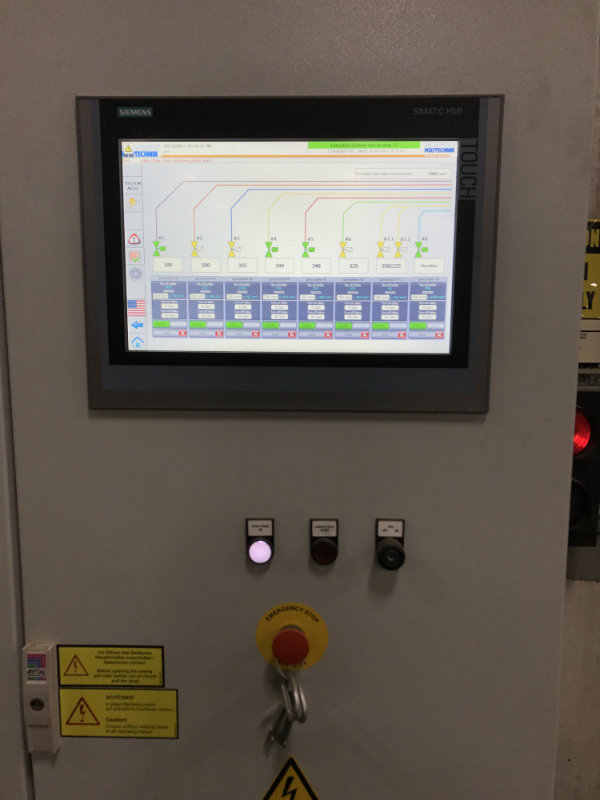

A Closer Look

Explore Höcker’s advanced Energy Management Systems in action

Energy-Saving Blast Gate Systems

Precision Airflow. Durable Performance.

Höcker’s ECO-MOT and ECO-P Blast Gate Systems are the perfect sidekick to our Energy Management Systems, delivering fast, automatic control over suction pipes to ensure precise airflow management. Unlike bulky, slow-moving traditional gates, ECO-MOT and ECO-P offer fast response times, minimal upkeep, and compact designs that fit right into your existing setup. With self-lubricating seals for smooth operation and low wear, you’ll keep things running efficiently with less downtime.

Key Features

Available Models

Tailored to Your Needs

Both models feature a compact design and lightweight build, allowing for quick installation and requiring minimal floor space — fitting easily into existing systems.

ECO-P

Features a double-sided pneumatic cylinder for quick, reliable suction. Opens and closes automatically in 1.5 seconds, making it ideal for high-demand environments where speed is essential.

ECO-MOT

Built for precision with a strong gear motor and push/pull chain drive. Opens in less than 6 seconds, delivering precise control, long-term reliability, and significant energy savings.

Safety & Technical Excellence

Safety and Durability

Höcker’s Energy Management Systems are built tough for safety and performance. Both the ECO-MOT and ECO-P models use heavy-duty, self-lubricating seals to reduce wear, and their rugged steel plates ensure they can withstand even the toughest industrial conditions. Noise-reduction features help keep your team comfortable, too.

- Pressure Resistance: Both models are rated low-pressure proof up to 3,500 Pa, ensuring safety and reliable performance under demanding conditions

Technical Specifications

- For suction-side use in dust removal systems

- Available diameters range from 100mm to 250mm (excluding 220/225mm)

ECO-P:

- Double-sided pneumatic cylinder for rapid opening and immediate suction

- Opening/closing time: Approximately 1.5 seconds with 100% activation duration

ECO-MOT:

- Strong gear motor with push/pull chain drive for precision and energy savings

- Opening time: Less than 6 seconds with 60% activation duration

Success Story

See Höcker’s advanced Energy Management System in action