Höcker North America’s Material Separators are like the ultimate workshop clean-up crew, creating a closed-loop system that keeps your energy efficient while handling woodworking waste with ease.

Whether managing sawdust, wood shavings, or coarse materials, these separators ensure reliable operation, all while slashing energy and heating costs. With a 99.9% clean air return rate and a compact design, they’ll keep your workspace cleaner, safer, and running like clockwork. Plus, they’re built to tackle a variety of tasks and seamlessly fit into your balers, compactors, and other waste systems in your woodworking operation.

Key Benefits

Product Insights

Smart Material Handling. Built for Efficiency.

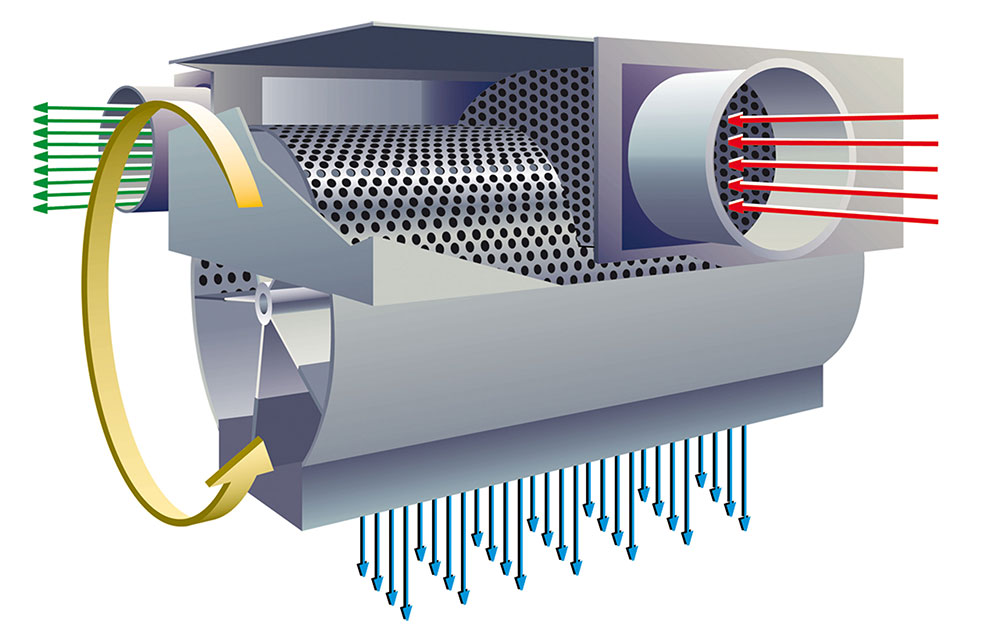

Höcker’s Material Separators are the unsung heroes of woodworking shops, effortlessly handling sawdust, wood shavings, and coarse waste, all while keeping energy use in check. Available in six sizes, these units can be customized to fit the specific air volume and material needs of your workshop. With a self-cleaning rotary airlock system, they keep things running smoothly and cut down on maintenance headaches.

Energy-Saving Performance

By keeping heat inside your workshop during colder months and returning clean air at a 99.9% rate, these separators not only reduce energy waste but also lower heating costs. Pair them with Höcker’s high-performance fans, and you’ve got a dust-extracting, energy-saving powerhouse that’ll keep your operation efficient and green.

Compact and Versatile Design

With a small footprint and low height, these separators fit right into your existing setup. Designed to handle coarse wood waste like wood shavings and chips, their high throughput volumes make them a smart choice for any woodworking shop. And with flexible feeding options (horizontal or vertical) and easy access for maintenance, they’re built for convenience and adaptability.

Available Models

Tailored to Your Needs

Höcker’s PMA Material Separators come in six flexible sizes, each customizable with inlet and outlet options to match your specific needs. The PMA-F version is designed specifically for the separation of specialized materials ensuring flexibility for more unique applications.

Key Features

Safety & Technical Excellence

Höcker’s Material Separators are designed to meet strict safety standards, ensuring reliable performance and the safety of your workers.

Safety & Compliance

- Continuous self-cleaning rotary airlock ensures consistent safety compliance

- Low-pressure design reduces wear and tear on equipment for consistent, safe operation

- Easily integrates with downstream filters for additional air quality control

Technical Specifications

- Available in six sizes with customizable inlet/outlet options

- 99.9% clean air return rate for excellent air quality in your workshop

- Seamlessly integrates with Höcker systems for pneumatic transport and filtration